在后处理程序中输出时间,对于编程加工的优化是再方便不过了,但是在MasterCAM的后处理程序中加入时间还是有相当难度的。

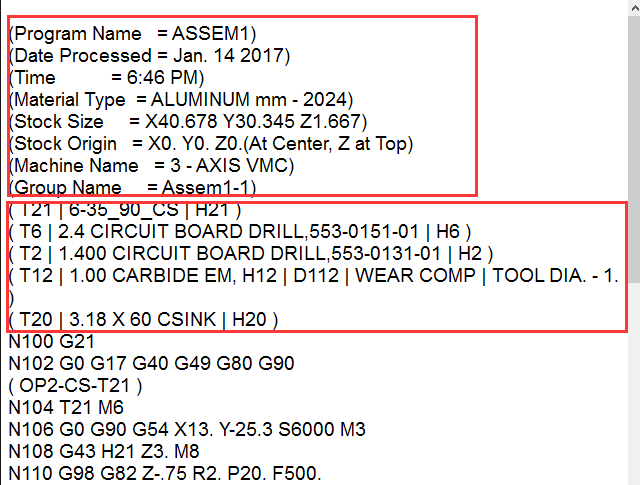

程序头的注释说明和刀具清单便于校对加工参数

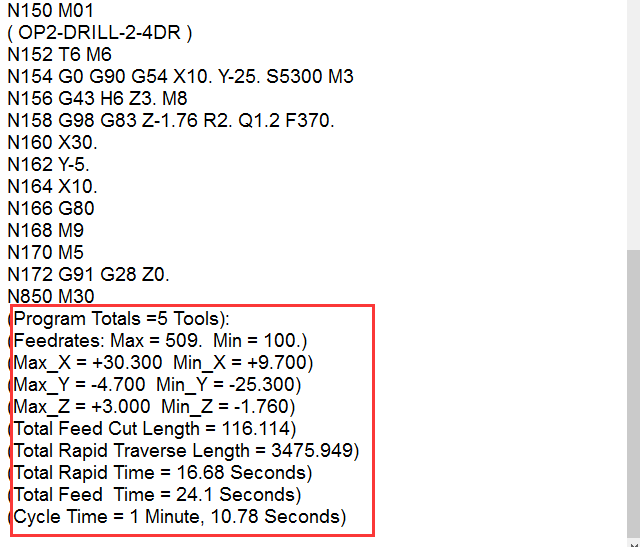

程序尾的统计说明便于优化已编好的加工程序

1. 一般输出设置项

# Specific setting to allow tuning the cycle time calculations

# Set the time it takes for machine to do a toolchange

tlchgtime : 0.1 #Tool Change Time (* in Minutes *)

time_est : 3 #Output operation and/or cycle times?

#0 = Do NOT output time estimates (including det_time estimates below)

#1 = Output operation time ONLY for EACH tool (not Program)

#2 = Output comeplete cycle time ONLY for entire Program

#3 = Output operation time for EACH tool AND cycle time for Program (if > 1 tool)

2. 加工时间输出设置

psof$ #Start of file for non-zero tool number

psetup #Call for toolchange info output

!op_id$

ptlchg0$ #Call from NCI null tool change (tool number repeats)

!gcode$

if op_id$ <> prv_op_id$, ptlchg$

!op_id$

ptlchg$ #Tool change - Output of time calculations for the last tool run

if op_id$ = prv_op_id$, ex$

ptooldata #Total ending data for tool (Path Length and Times)

tmax_fr = fr_pos$ #Initialize (max fr used in current tool)

tmin_fr = fr_pos$ #Initialize (min fr used in current tool)

comment$

psetup #Call for toolchange info output

!op_id$

peof0$ #End of file for tool zero

peof$

peof$ #End of file for non-zero tool - Output of time calculations for the last tool and total time

ptooldata #Total ending data for tool (Path Length and Times)

#Supress Program totals if only one tool or no output selected

if tcnt > one & (fr_limits | xyz_limits | show_lengths | time_est),

3.快速和进给长度及时间和总加工时间的输出

#Output Feed/Rapid path lengths

if show_lengths = two | show_lengths = three,

[

"Total Feed Cut Length = ", *llen_total, e$

"Total Rapid Traverse Length = ", *rlen_total, e$

#sepline, e$ #Output the separator '----' line

]

#Output Rapid/Feedrate times

if time_est > 0 & (det_time = two | det_time = three),

[

ttltime = tot_rtime

"Total Rapid Time = ", ptimeout, e$

ttltime = tot_ltime

"Total Feed Time = ", ptimeout, e$

#sepline, e$ #Output the separator '----' line

]

#Output Cycle Time information

if time_est = two | time_est = three,

[

ttltime = total #Transfer TOTAL program time

"Cycle Time = ", ptimeout, e$ #Program Total time output

]

]

4.时间单位的相互转换

pthrminsec #Convert minutes to hr/min/sec format

thrs = int(ttltime / 60)

tmin = int(ttltime - thrs * 60)

tsec = (ttltime - thrs * 60 - tmin) * 60

5.总加工时间的组成

pttltime #Total tool times and total program time

tot_ltime = tot_ltime + tltime #Total FEED time

tot_rtime = tot_rtime + trtime #Total RAPID time

ttltime = tltime + trtime #Calc. current Tool Time

total = ttltime + total + tlchgtime #Calc. total Program Time

6.输出时间的格式

ptimeout #Output "times"

pthrminsec #Convert minutes to hr/min/sec format

#Output 'HOURS'

if thrs = one, *thrs, " Hour, "

if thrs > one, *thrs, " Hours, "

#Output 'MINUTES'

if tmin = one, *tmin, " Minute, "

if tmin > one, *tmin, " Minutes, "

#Output 'SECONDS'

if tsec > zero, *tsec, " Seconds"

7.快速进给时间和长度的计算原理及变量

ptimer #Rapid time and length calc

rlen = rlen + len #Running total RAPID length

trtime = rlen / pst_rpd_fr$ #Running total RAPID time

ptimel #Feed time and length calc

if fr_pos$ < zero, fr_pos$ = prv_fr_pos$

if fr_pos$ < tol, fr_pos$ = tol

llen = llen + len

tltime = tltime + len / fr_pos$

8.切削进给时间和长度的计算原理及变量

ptimel #Feed time and length calc

if fr_pos$ < zero, fr_pos$ = prv_fr_pos$

if fr_pos$ < tol, fr_pos$ = tol

llen = llen + len

tltime = tltime + len / fr_pos$

9.空间3D长度的计算原理及变量

ptime #Distance calculations

dx = x$ - prv_x$

dy = y$ - prv_y$

dz = z$ - prv_z$

len = sqrt(dx^2 + dy^2 + dz^2)

if gcode$ = zero, ptimer #RAPID time and length calc

if gcode$ = one, ptimel #FEED time and length calc

!x$, !y$, !z$, !fr_pos$ #Update previous [prv_?] variables

if fr_limits, pfrcheck #Track MAX/MIN Feedrates if requested

10.有关加工时间相关变量的格式

# Format assignments

# --------------------------------------------------------------------------

fmt 9 progno$ #Program number

fmt 3 t$ #Tool number

fmt 7 tldia$ #Tool diameter

fmt 7 tcr$ #Tool corner radius

fmt 3 tloffno$ #Diameter offset number

fmt 3 tlngno$ #Length offset number

fmt 3 ss$ #Spindle speed

fmt 4 fr_pos$ #Feedrate

fmt 2 llen #Feed cut length

fmt 2 rlen #Rapid traverse cut length

fmt 2 llen_total #Feed cut length (program total)

fmt 2 rlen_total #Rapid traverse cut length (program total)

fmt 2 total #Total part time

fmt 2 ttltime #Total operation time

fmt 3 thrs #Time in hours

fmt 3 tmin #Time in minutes

fmt 8 tsec #Time in seconds

fmt 3 tcnt #Tool Counter

fmt 3 custcycle #Custom Cycle number

fmt 4 tmax_fr #Max Feedrate in current Tool

fmt 4 tmin_fr #Min Feedrate in current Tool

fmt 4 pmax_fr #Max Feedrate in Program

fmt 4 pmin_fr #Min Feedrate in Program

将以上内容加入到现有后处理中,配以适当的位置便可以在后处理出的NC程序中输出加工时间,其中的快速进给是机床默认的12500mm/min,切削进给在编程参数中设定,换刀时间(tlchgtime : 0.0333 #Tool Change Time (* in Minutes *)可以根据具体机床设定,本程序设定0.3333分钟,大概是2秒。

其总加工时间( CYCLE TIME)=快速进给时间+切削进给时间+换刀时间;基本吻合实际生产加工时间。

*今日切削*

加工方式:Dynamic roughing (动态加工)

切削材料:AL6061-T6 (铝材 6061)

使用刀具: ISCAR 0.750 Chatterfree (依斯卡 0.75英才防振立铣刀)

切削步距: 40% stepover (刀具直径 X 40%)

切削深度: 1.15 stepdown. (1.15英寸)