fanuc及siemens系统参数修改刀补倒圆角宏程序

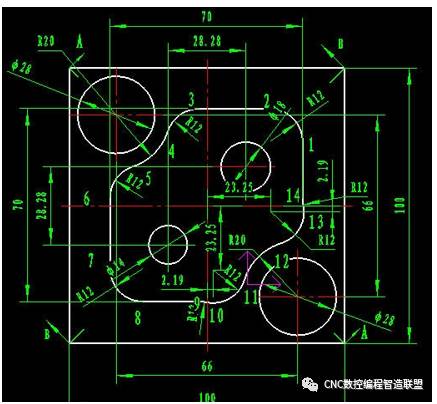

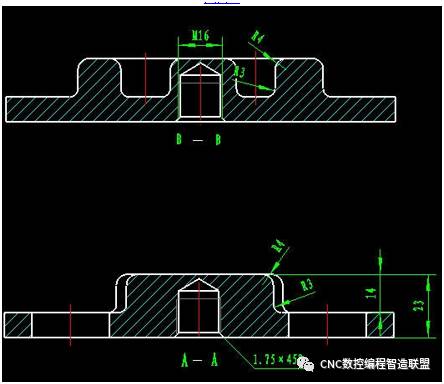

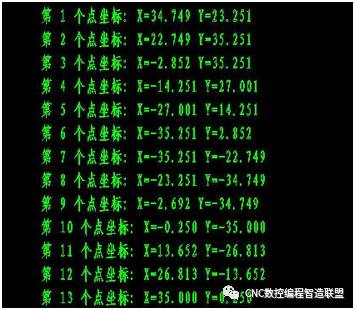

图片1

图片2

图片3

图片4

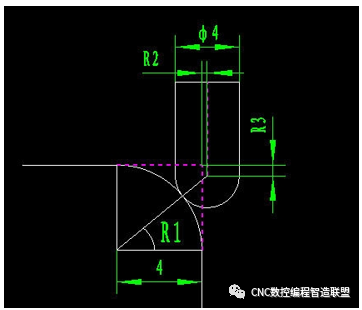

圆角半径4mm,刀具半径2mm,R1为角度参数,初始值为90,即从圆角上表面开始加工,即工件上表面;当R1=0时,则加工到圆角最低点,即轮廓的侧面。

西门子参考程序:

M03S2500;

G90G54G64G00X0Y0Z50;

G01X54.749Y23.251F200; 下刀点

G01Z5;

R1=90;赋初始值

KK: R2=6*COS(R1)-4; 刀补值,为刀具中心距离轮廓线的垂直距离,6是刀具与圆角的半径之和

R3=6*SIN(R1)-4;每一圈加工时的下刀深度,当对球刀时为球刀最低点时,-4,当对刀点为球刀中心时,则-6

$TC_DP6[1,1]=R2; 设定刀补值,1号刀1号刀补

G01Z=R3F100;

G42G01X54.749Y3.251D1;

G02X34.749Y23.251CR=20;

G03X22.749Y35.251CR=12;

G01X-2.852Y35.251;

G03X-14.251Y27.001CR=12;

G02X-27.001Y14.251CR=20;

G03X-35.251Y2.852CR=12;

G01X-35.251Y-22.749;

G03X-23.251Y-34.749CR=12;

G01X-2.692Y-34.749;

G02X-0.25Y-35CR=12;

G03X13.652Y-26.813CR=12;

G02X26.813Y-13.652CR=20;

G03X35Y0.25CR=12;

G02X34.749Y2.692CR=12;

G01X34.749Y23.251;

G02X54.749Y43.251CR=20;

G40G01X54.749Y23.251;

R1=R1-5;

IF R1>=0 GOTOBKK;

G00Z50;

M05;

M30;

FANUC宏程序示例:

西门子参考程序:

M03S2500;

G90G54G64G00X0Y0Z50;

G01X54.749Y23.251F200; 下刀点

G01Z5;

R1=90; 赋初始值

N10#2=6*COS[#1]-4; 刀补值,为刀具中心距离轮廓线的垂直距离,6是刀具与圆角的半径之和

#3=6*SIN[#1]-4;每一圈加工时的下刀深度,当对球刀时为球刀最低点时,-4,当对刀点为球刀中心时,则-6

G10L12P1R#2; 设定刀补值,1号刀1号刀补

G01Z[#3]F100;

G42G01X54.749Y3.251D01;

G02X34.749Y23.251R=20;

G03X22.749Y35.251R=12;

G01X-2.852Y35.251;

G03X-14.251Y27.001R=12;

G02X-27.001Y14.251R=20;

G03X-35.251Y2.852R=12;

G01X-35.251Y-22.749;

G03X-23.251Y-34.749R=12;

G01X-2.692Y-34.749;

G02X-0.25Y-35R=12;

G03X13.652Y-26.813R=12;

G02X26.813Y-13.652R=20;

G03X35Y0.25R=12;

G02X34.749Y2.692R=12;

G01X34.749Y23.251;

G02X54.749Y43.251R=20;

G40G01X54.749Y23.251;

#1=#1-5;

IF [#1GE0] GOTO 10;

G00Z50;

M05;

M30;